If you’re searching for the top industrial-grade protocol analyzers, I’ve found 13 options that deliver exceptional precision, durability, and performance. From robust CAN and CAN FD analyzers with electrical isolation to advanced power monitors and navigation sensors, these tools are designed for harsh environments and high-speed data analysis. They support multiple protocols, OS compatibility, and come with detailed software. Keep exploring further to discover which one best fits your needs for reliable system diagnostics.

Key Takeaways

- Highlights the top industrial-grade protocol analyzers with robust hardware, high data speeds, and extensive protocol support.

- Emphasizes durability features such as shockproof design, corrosion resistance, and electrical isolation for harsh environments.

- Details versatile software tools for real-time monitoring, data filtering, and multi-network analysis across various OS platforms.

- Discusses applications in industrial automation, vehicle diagnostics, power systems, and system debugging for reliable data analysis.

- Provides insights into device reliability, support options, and considerations for choosing high-performance protocol analyzers.

If you’re looking for an affordable yet reliable industrial-grade protocol analyzer, the Waveshare Industrial CAN/CAN FD Bus Data Analyzer is a great choice. It offers dual CAN FD interfaces with electrical isolation and protection circuits, ensuring stable operation in tough environments. Its compact size and user-friendly setup make it ideal for learning, debugging, and integration into industrial or automotive systems. The device supports Windows systems with dedicated drivers and tools for data capture, filtering, and analysis. While some users encounter driver or software limitations, its fast data reception and robust build make it a valuable tool for secondary development and industrial communication testing.

Best For: industrial engineers, automotive technicians, and developers seeking a reliable, compact CAN/CAN FD protocol analyzer for learning, debugging, and system integration.

Pros:

- Dual CAN FD interfaces with electrical isolation enhance reliability in harsh environments

- Compact design and user-friendly setup simplify installation and operation

- Supports Windows with dedicated drivers and tools for comprehensive data analysis

Cons:

- Limited software features and message configuration options may require additional development

- Driver installation can be challenging for some users

- Lacks compatibility with certain third-party CAN software like CAN BusMaster

Waveshare Industrial Grade CAN Bus Data Analyzer

The Waveshare Industrial Grade CAN Bus Data Analyzer stands out for its dual independent CAN FD interfaces, making it ideal for professionals who need reliable, high-performance data monitoring in demanding industrial environments. Its onboard electrical isolation and protection circuits ensure stable operation amid electrical noise and harsh conditions. Compact and user-friendly, it supports both Windows and Linux, making integration straightforward for debugging, learning, or development tasks. With extensive software tools, drivers, and tutorials, it enables efficient data analysis, collection, and bus monitoring. Whether for industrial automation, power communication, or intelligent control, this analyzer delivers the precision and dependability essential for critical applications.

Best For: professionals and engineers in industrial automation, power communication, and intelligent control sectors seeking reliable high-performance CAN bus data monitoring and analysis.

Pros:

- Supports dual independent CAN FD interfaces with electrical isolation for enhanced reliability

- Compatible with both Windows and Linux operating systems for versatile integration

- Comes with comprehensive software tools, drivers, and tutorials for easy setup and use

Cons:

- May be relatively costly for small-scale or hobbyist projects

- Limited to industrial-grade applications, potentially over-spec for casual use

- Requires some technical knowledge for optimal setup and operation

Industrial CAN/CAN FD Data Analyzer and USB Adapter

When working with industrial automation and power communication systems, having a reliable and high-performance protocol analyzer is essential. The Industrial CAN/CAN FD Data Analyzer and USB Adapter offers just that, providing high-speed USB to CAN FD connectivity with dual independent interfaces. It supports standard and extended CAN frames, with baud rates from 100 Kbps to 5 Mbps, ensuring versatile communication. Equipped with electrical isolation and protection circuits, it guarantees stability in harsh environments. Compatible with Windows systems and bundled with drivers, software, and tutorials, this device is ideal for debugging, data collection, and integration in industrial and power control applications.

Best For: professionals and engineers involved in industrial automation, power communication, and intelligent control systems seeking high-performance, reliable CAN FD data analysis and troubleshooting tools.

Pros:

- Supports high-speed CAN FD and standard CAN protocols with baud rates up to 5 Mbps for versatile communication needs

- Equipped with dual independent electrical-isolated CAN FD interfaces, enhancing stability and security in harsh environments

- Includes comprehensive software, drivers, and tutorials for easy setup, secondary development, and integration

Cons:

- Limited customer reviews, with only one review available, which may affect confidence in long-term reliability

- The product’s niche application may require specialized knowledge for optimal use

- Slightly higher price point due to industrial-grade features and robust protection circuits

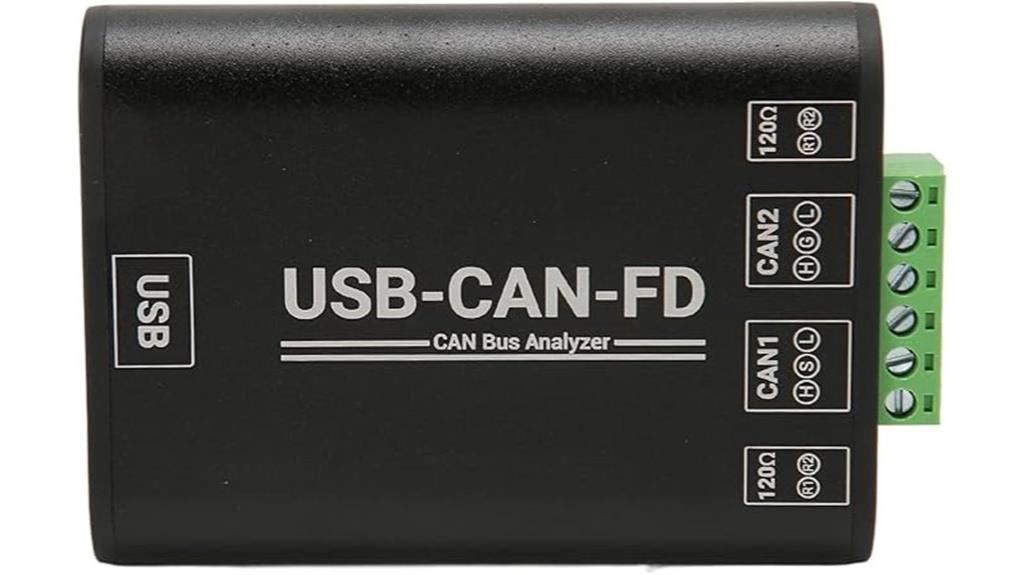

Industrial CAN/CAN FD Bus Data Analyzer (USB-CAN-FD-B)

Designed for professionals who need reliable, high-speed monitoring of multiple CAN networks simultaneously, the Industrial CAN/CAN FD Bus Data Analyzer (USB-CAN-FD-B) stands out with its support for up to 128 devices on a single PC. It features onboard high-speed USB 2.0, dual CAN/CAN FD interfaces supporting independent bidirectional operation, and compatibility with CAN 2.0A, 2.0B, ISO11898-1, and CAN FD Protocol V.1.0. Its high-performance 32-bit MIPS M4K core ensures stability, while full signal and power isolation enhance security. With configurable baud rates up to 5 Mbps and extensive software support, it’s ideal for thorough multi-network data analysis and verification.

Best For: professionals and engineers requiring high-speed, reliable monitoring and analysis of multiple CAN and CAN FD networks simultaneously in industrial environments.

Pros:

- Supports up to 128 devices on a single PC for extensive multi-network monitoring.

- Fully compliant with multiple CAN standards including CAN 2.0A, 2.0B, ISO11898-1, and CAN FD Protocol V.1.0.

- Equipped with high-performance 32-bit MIPS core and full signal/power isolation for stability and security.

Cons:

- Requires compatible software and configuration tools for optimal operation.

- May be over-specification for users with only single or minimal CAN network monitoring needs.

- USB 2.0 interface, which might limit data transfer speed compared to newer USB standards.

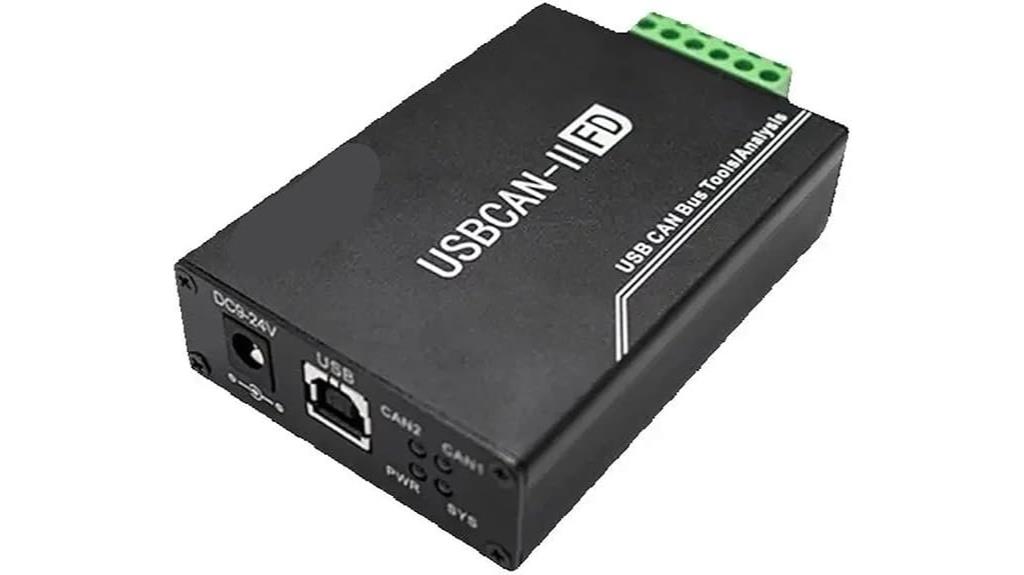

Keenso CAN FD Protocol Data Analyzer USB to CAN FD Converter

If you’re seeking a reliable, high-performance protocol analyzer for industrial applications, the Keenso CAN FD Protocol Data Analyzer USB to CAN FD Converter stands out. It supports multiple protocols, including CAN2.0A/B and CAN FD, making it versatile across various systems. With the ability to transfer up to 20,000 frames per second, it ensures fast, efficient data communication. The device features indicator lights for power, system status, and channel activity, providing clear operational feedback. Built from durable aluminum alloy, it’s designed for long-lasting performance in tough industrial environments. Overall, it’s an industrial-grade converter and data analyzer that combines speed, durability, and ease of use.

Best For: industrial professionals and engineers needing high-speed, reliable protocol analysis and data transfer across multiple CAN systems.

Pros:

- Supports multiple protocols including CAN2.0A/B and CAN FD for versatile application.

- Transmits up to 20,000 frames per second for efficient high-speed data transfer.

- Durable aluminum alloy construction ensures long-lasting performance in industrial environments.

Cons:

- May require technical knowledge for optimal setup and operation.

- Limited compatibility with non-standard or proprietary CAN protocols.

- The device’s advanced features might be excessive for casual or low-volume users.

Industrial CAN/CAN FD Bus Protocol Data Analyzer and USB to CAN FD Adapter

The Industrial CAN/CAN FD Bus Protocol Data Analyzer and USB to CAN FD Adapter stands out as an essential tool for engineers and technicians who need reliable, high-speed data analysis of CAN networks. It connects via USB to PCs or industrial controllers, supporting protocols like CAN 2.0A, 2.0B, ISO11898-1, and CAN FD V.1.0. With two independent CAN/CAN FD channels, it enables bidirectional transmission and real-time monitoring. Its compact, user-friendly design makes it ideal for learning, debugging, and industrial applications. Compatible with Windows XP through 11, it includes drivers, tools, and tutorials, ensuring seamless integration into diverse communication and control systems.

Best For: engineers, technicians, and industrial automation professionals seeking reliable, high-speed CAN bus data analysis and debugging tools for industrial and power communication systems.

Pros:

- Supports a wide range of protocols including CAN 2.0A, 2.0B, ISO11898-1, and CAN FD V.1.0 for versatile application.

- Dual independent CAN/CAN FD channels enable bidirectional data transmission and real-time network monitoring.

- Compatible with Windows XP through 11, providing broad system support and easy integration with existing setups.

Cons:

- May require technical expertise for setup and secondary development integration.

- Limited to USB connection, which might not be suitable for applications requiring wireless or network-based access.

- The product’s features are specialized; it might be more than what casual users or hobbyists need.

Industrial CAN/CAN FD Bus Data Analyzer (USB-CAN-FD-B)

Looking for a reliable solution to analyze CAN and CAN FD bus networks across various industrial environments? The Industrial CAN/CAN FD Bus Data Analyzer (USB-CAN-FD-B) offers robust, industrial-grade performance with onboard dual independent CAN FD interfaces, electrical isolation, and multiple protection circuits. Its compact design makes it easy to deploy for learning, debugging, or industrial integration. It supports Windows, Linux, Raspberry Pi OS, Ubuntu, and VMware virtual machines, with an upgraded version that includes Linux system support. The device allows for transceiver control, data collection, and real-time monitoring, making it ideal for industrial, power communication, and control applications.

Best For: professionals and developers seeking reliable, industrial-grade CAN/CAN FD bus network analysis, monitoring, and debugging across diverse environments such as manufacturing, power systems, and automation.

Pros:

- Supports multiple operating systems including Windows, Linux, Raspberry Pi OS, and VMware, ensuring versatile deployment options.

- Equipped with dual independent CAN FD interfaces featuring electrical isolation and protection circuits for robust industrial use.

- Compact and easy-to-use design suitable for learning, debugging, and industrial integration.

Cons:

- May require some technical expertise for setup and secondary development integration.

- Advanced features or software updates might necessitate additional licensing or support.

- Limited to USB connection, which might restrict mobility in certain remote or field applications.

Industrial USB to Can FD Adapter, Protocol Data Analyzer

For professionals needing reliable and precise bus communication analysis, the Industrial USB to CAN FD Adapter stands out as an essential tool. It features two independent, fully isolated CAN FD channels with 3000V DC galvanic isolation, ensuring stable and interference-free data transmission. Made from durable aluminum alloy, it’s compact and built for long-term industrial use. The adapter supports various software tools, drivers, and tutorials, facilitating easy integration, control, and data monitoring via USB connection. Ideal for debugging, learning, and system development, it’s perfect for industrial communication, power systems, and automation projects. Its robust design and versatile capabilities make it a top choice for demanding industrial environments.

Best For: professionals and engineers requiring reliable, high-precision bus communication analysis and industrial automation solutions.

Pros:

- Fully isolated CAN FD channels with 3000V DC galvanic isolation for interference-free operation

- Durable aluminum alloy construction suitable for long-term industrial use

- Supports comprehensive software tools, drivers, and tutorials for easy integration and control

Cons:

- May require technical expertise to fully utilize advanced features and software support

- Size and weight may be less portable compared to smaller adapters for field use

- Price may vary and could be higher than basic CAN adapters due to industrial-grade features

Industrial-Grade CANbus Data Analyzer (USB to CAN FD Interface)

Industrial-Grade CANbus Data Analyzer with a USB to CAN FD interface is ideal for professionals who need reliable, high-speed data transfer in demanding industrial environments. It supports data rates from 100kbps to 5Mbps and features a programmable logic circuit for customized analysis. Compatible with CAN2.0A and B protocols, it adheres to ISO11898-1 standards, ensuring broad compatibility. The dual CAN FD interface offers flexible communication, while the 2500V isolation enhances safety and noise immunity. Compact and lightweight, it requires no batteries, making it perfect for on-site use. This analyzer delivers robust performance, combining high speed, durability, and ease of integration for industrial data monitoring.

Best For: professionals and engineers requiring reliable, high-speed CANbus data analysis in demanding industrial environments.

Pros:

- Supports a wide data rate range from 100kbps to 5Mbps for versatile applications

- Equipped with dual CAN FD interfaces for flexible communication options

- No batteries needed, ensuring ease of use and maintenance in industrial settings

Cons:

- Price and availability may vary depending on retailer and location

- Requires technical knowledge for optimal configuration and use

- Limited information on software support or compatibility with specific data analysis tools

Industrial-Grade CANbus Data Analyzer (USB to CAN FD Interface)

If you need a reliable and high-speed solution for analyzing CANbus data in demanding industrial environments, this USB to CAN FD interface is an excellent choice. It supports baud rates from 100Kbps up to 5Mbps, ensuring fast and flexible data transfer. With dual CAN FD channels and compliance with ISO11898-1 standards, it handles CAN2.0A and B protocols effortlessly. The device features a robust 2500V electrical isolation, protecting your system from surges. Compact and easy to use, it requires no assembly. Manufactured by UOFKIPBA, it’s ideal for automation, vehicle diagnostics, and network analysis, delivering dependable performance in tough industrial settings.

Best For: professionals and engineers needing high-speed, reliable CANbus data analysis in industrial automation, vehicle diagnostics, and network systems.

Pros:

- Supports a wide baud rate range from 100Kbps to 5Mbps for versatile data transfer.

- Equipped with dual CAN FD channels and ISO11898-1 compliance for broad protocol compatibility.

- Features robust 2500V electrical isolation, ensuring system protection and durability.

Cons:

- Price and availability may vary across different online and offline stores.

- No built-in display or user interface; requires connection to a computer for operation.

- Compact size might limit ease of handling for some users during installation or troubleshooting.

The Industrial Beidou Navigation Sensor with GPS-IMU, Accelerometers, and Gyroscopes stands out as an essential tool for professionals requiring highly accurate inertial and positional data in demanding environments. This 6-axis device combines accelerometers, gyroscopes, magnetometers, barometers, and GPS, delivering precise measurements of angles, acceleration, magnetic heading, altitude, and ground speed. With a static accuracy of 0.05° and dynamic accuracy of 0.1°, it guarantees reliable performance in static or dynamic conditions. Managed by a high-performance processor and advanced fusion algorithms, it provides stable, low-noise data suited for industrial navigation, orientation, and positioning applications.

Best For: professionals in industrial navigation, orientation, and positioning requiring highly accurate inertial and GPS data in challenging environments.

Pros:

- High static (0.05°) and dynamic (0.1°) measurement accuracy for precise navigation and orientation.

- Integrated multi-sensor suite (GPS, IMU, magnetometer, barometer) for comprehensive data collection.

- Stable, low-noise output with advanced fusion algorithms, ensuring reliable performance in various conditions.

Cons:

- May require technical expertise for optimal integration and calibration.

- Potentially higher cost due to advanced sensor technology and robust construction.

- Limited information on real-time data processing capabilities without additional hardware or software.

Three-Phase AC Power Monitor PZEM-6L24 with RS485 Communication

For professionals who need accurate and reliable power monitoring in demanding environments, the Three-Phase AC Power Monitor PZEM-6L24 with RS485 communication stands out. It offers laboratory-grade measurement accuracy (1%) for voltage, current, power, energy, power factor, frequency, and phase angle, making it suitable for automation panels, IoT projects, and electricity meters. Its rugged design and seamless integration via RS485 and TTL UART support ensure dependable operation under harsh conditions. With adjustable baud rates, configurable addressing, pulse output, and security features, this device delivers precise diagnostics and long-term performance, making it an essential tool for industrial power management.

Best For: professionals and industrial engineers seeking precise, reliable three-phase power monitoring and diagnostics in demanding environments.

Pros:

- Laboratory-grade measurement accuracy (1%) for comprehensive electrical parameters.

- Rugged, industrial-grade design suitable for harsh conditions and long-term deployment.

- Supports flexible communication options with adjustable baud rates, addressing, and pulse output for seamless integration.

Cons:

- Requires technical knowledge for proper wiring and configuration.

- May have higher initial cost compared to basic energy meters.

- Limited to RS485 and UART interfaces, which might require additional adapters for some systems.

3-Phase Power Meter with RS485 Modbus Protocol

A high-precision 3-phase power meter with RS485 Modbus protocol stands out as an ideal choice for industrial environments that demand reliable energy monitoring and seamless system integration. It offers Class 1 accuracy (±1%), measuring current up to 80A directly or higher with CTs, and voltage up to 1000V with PTs. Its wide temperature tolerance (-25℃ to +60℃), certifications (CE, RCM, UKCA), and support for multiple grid configurations make it versatile. The device features a multi-parameter LCD display, supports customizable settings, and connects effortlessly via RS485 for real-time data exchange. Its durable, DIN rail-mounted design ensures easy installation in demanding industrial settings.

Best For: industrial facilities and commercial power systems requiring precise, reliable energy monitoring and seamless integration with automation systems.

Pros:

- High-precision Class 1 accuracy (±1%) ensures reliable energy data.

- Flexible voltage and current measurement capabilities, supporting up to 1000V and 80A directly or via CTs.

- Robust, DIN rail-mounted design with wide temperature tolerance (-25℃ to +60℃) for harsh environments.

Cons:

- External PTs are necessary for voltages exceeding 500V, adding to installation complexity.

- Limited communication speed options, with a default of 9600bps, which may require adjustment for high-speed needs.

- May require technical expertise for configuration of ratios, wiring modes, and protocol settings during setup.

Factors to Consider When Choosing Industrial‑Grade Protocol Analyzers

When selecting an industrial-grade protocol analyzer, I always start by checking its compatibility with the protocols I work with. I also consider data transfer speeds, durability, and software support to make certain it meets my needs. These factors help me choose a reliable tool that performs well in demanding industrial environments.

Compatibility With Protocols

Choosing the right industrial-grade protocol analyzer hinges on guaranteeing it supports all the communication standards relevant to your network. I look for devices that handle protocols like CAN 2.0A/B, CAN FD, and ISO11898-1, along with any industry-specific protocols I need. It’s vital that the analyzer can manage the maximum data rates of my network, often between 100 Kbps and over 5 Mbps in high-speed environments. Compatibility with both standard and extended frame formats assures I can analyze all traffic types thoroughly. I also verify support for protocol versions and features like baud rate auto-detection for flexible setup. Finally, I check that the device integrates smoothly with my existing hardware and software, including multi-platform compatibility and options for secondary development.

Data Transfer Speed

Higher data transfer speeds are indispensable for real-time monitoring and efficient analysis of protocol communications. Industrial-grade protocol analyzers support data rates from 100 Kbps to over 5 Mbps, depending on the network’s demands. Faster speeds reduce latency, allowing for accurate capture of high-frequency signals in complex systems. They also enable more data to be logged and analyzed within a set timeframe, which is critical for identifying issues quickly. Selecting an analyzer with a transfer speed that matches or exceeds your network’s bandwidth is essential to prevent data loss and guarantee comprehensive insights. By prioritizing higher transfer rates, you ensure your analysis tools keep pace with your network’s performance, leading to more reliable diagnostics and smoother troubleshooting processes.

Electrical Isolation Levels

Electrical isolation levels are vital factors to contemplate because they determine a protocol analyzer’s ability to withstand voltage transients and prevent damage. These levels are typically rated in volts or kilovolts, indicating the maximum voltage the device can handle without breaking down. Higher ratings, such as 2500V or 3000V, offer enhanced protection against voltage surges and ground loops, which are common in industrial settings. Proper isolation prevents high-voltage transients from harming connected equipment or corrupting data signals, ensuring data integrity. It also improves noise immunity, essential in environments with high electromagnetic interference. Selecting an analyzer with adequate electrical isolation is essential for safety compliance and reliable data acquisition, especially when monitoring multiple networks with different ground potentials.

Device Durability and Build

The build quality and physical durability of an industrial-grade protocol analyzer directly impact its ability to perform reliably in demanding environments. These devices are constructed with tough materials like aluminum alloy or reinforced plastics to resist impact, vibration, and mechanical stress. Protective circuits, electrical isolation up to 3000V, and corrosion-resistant coatings ensure long-term operation in harsh conditions. Their shockproof and vibration-resistant components maintain performance even under extreme physical forces. Compact, lightweight designs make installation easier in space-constrained areas, while secure connectors with locking mechanisms prevent damage from frequent connections. Overall, a robust construct enhances reliability, reduces downtime, and ensures consistent data capture in challenging industrial environments. Prioritizing durability means fewer failures and more dependable operation over time.

Software Support and Tools

When selecting an industrial-grade protocol analyzer, ensuring robust software support is essential for smooth operation and efficient troubleshooting. Effective software includes comprehensive drivers, tools, and tutorials that simplify setup and problem-solving. Compatibility with multiple operating systems like Windows, Linux, Raspberry Pi OS, or VMWare expands flexibility across diverse industrial environments. Advanced analysis software offers features such as data filtering, real-time monitoring, replay capabilities, and multi-channel data capture, streamlining debugging processes. The availability of secondary development examples in languages like C#, Python, and LabVIEW allows for customization and seamless integration into larger systems. Regular updates, intuitive interfaces, and detailed documentation are vital for maintaining reliability, minimizing downtime, and ensuring the analyzer performs optimally over time.

Ease of Integration

Choosing an industrial-grade protocol analyzer that integrates smoothly into your existing systems requires careful consideration of several key factors. First, support for multiple communication interfaces like USB, Ethernet, or serial ports is essential for seamless connectivity across different setups. Compatibility with standard industrial protocols such as CAN, CAN FD, Modbus, and Ethernet/IP ensures smooth integration into diverse network environments. Configurable baud rates and protocol settings allow quick adaptation to various operational parameters without hardware modifications. Additionally, support for SDKs or APIs enables developers to customize workflows and automate data analysis, saving time and reducing errors. Clear documentation, including installation guides and tutorials, is crucial for minimizing setup time and technical barriers, ensuring the analyzer fits effortlessly into your existing infrastructure.

Price and Support Options

Evaluating the price and support options for industrial-grade protocol analyzers makes certain you get the best value without sacrificing quality. I recommend comparing prices across online and offline stores to guarantee you’re getting a fair deal. Look for vendors that offer thorough support, including detailed documentation, tutorials, and development examples, which ease integration and troubleshooting. Verify if the manufacturer provides warranties and post-sales services to handle potential issues over the device’s lifespan. Clear contact channels and accessible technical support resources are essential for timely assistance and software updates. Additionally, consider feedback systems that let users report lower prices—these can help you negotiate discounts or access better support options. Balancing cost with rigorous support ensures dependable performance and peace of mind.

Frequently Asked Questions

What Certifications Ensure the Safety of Industrial Protocol Analyzers?

Certifications like UL, CE, and IEC guarantee the safety of industrial protocol analyzers. I look for UL certification because it verifies compliance with safety standards in the US, while CE indicates conformity with European Union safety regulations. IEC standards cover broader international safety and performance criteria. When choosing an analyzer, I always check for these certifications to ensure reliability, safety, and adherence to global standards, giving me peace of mind during operation.

How Do Environmental Conditions Impact Analyzer Performance?

Environmental conditions like temperature, humidity, and electromagnetic interference directly impact analyzer performance. I’ve seen data inaccuracies occur when temps fluctuate or humidity rises, causing hardware issues. Electromagnetic interference can disrupt signals, making analysis unreliable. To guarantee precision, I always recommend maintaining stable environmental conditions, shielding equipment properly, and monitoring surroundings regularly. This way, your analyzer remains accurate and dependable, even in challenging industrial settings.

Can These Analyzers Interface With Multiple Protocols Simultaneously?

Absolutely, these analyzers act like skilled orchestra conductors, seamlessly managing multiple protocols at once. They’re designed with advanced hardware and software that let me monitor, decode, and troubleshoot various communication standards simultaneously. This multitasking ability guarantees I get an all-inclusive view of complex industrial networks without missing a beat. So, yes, they’re built to handle multiple protocols, making my job easier and more efficient, all while maintaining pinpoint accuracy.

What Maintenance Practices Extend the Lifespan of Industrial Analyzers?

Regularly calibrate and update your industrial analyzers to guarantee accuracy and reliability. Keep them clean and free of dust, moisture, and debris to prevent damage and maintain ideal performance. Store devices properly when not in use, avoiding extreme temperatures and humidity. Conduct routine inspections for wear or damage, and follow manufacturer guidelines for maintenance schedules. Proper care not only extends their lifespan but also guarantees precise measurements when you need them most.

Are Firmware Updates Necessary for Compatibility With New Protocols?

Firmware updates are absolutely essential for maintaining compatibility with new protocols; skipping them is like trying to run the latest software on an ancient computer—ineffective. I always recommend staying current because updates often include critical bug fixes, security patches, and support for emerging standards. By keeping your analyzer’s firmware up to date, you guarantee it operates smoothly, reliably, and can handle the newest protocols seamlessly, saving you headaches down the line.

Conclusion

I know choosing the right industrial protocol analyzer can seem overwhelming, but investing in a high-quality device guarantees reliability and precision I can count on. Don’t let the complexity hold you back—these analyzers are built to simplify troubleshooting and boost your system’s performance. If you’re worried about compatibility, rest assured many of these options work seamlessly with popular industrial networks. Trust me, the right analyzer makes all the difference in maintaining smooth operations.